Shanghai Aolin Auto Safety System Co., Ltd.

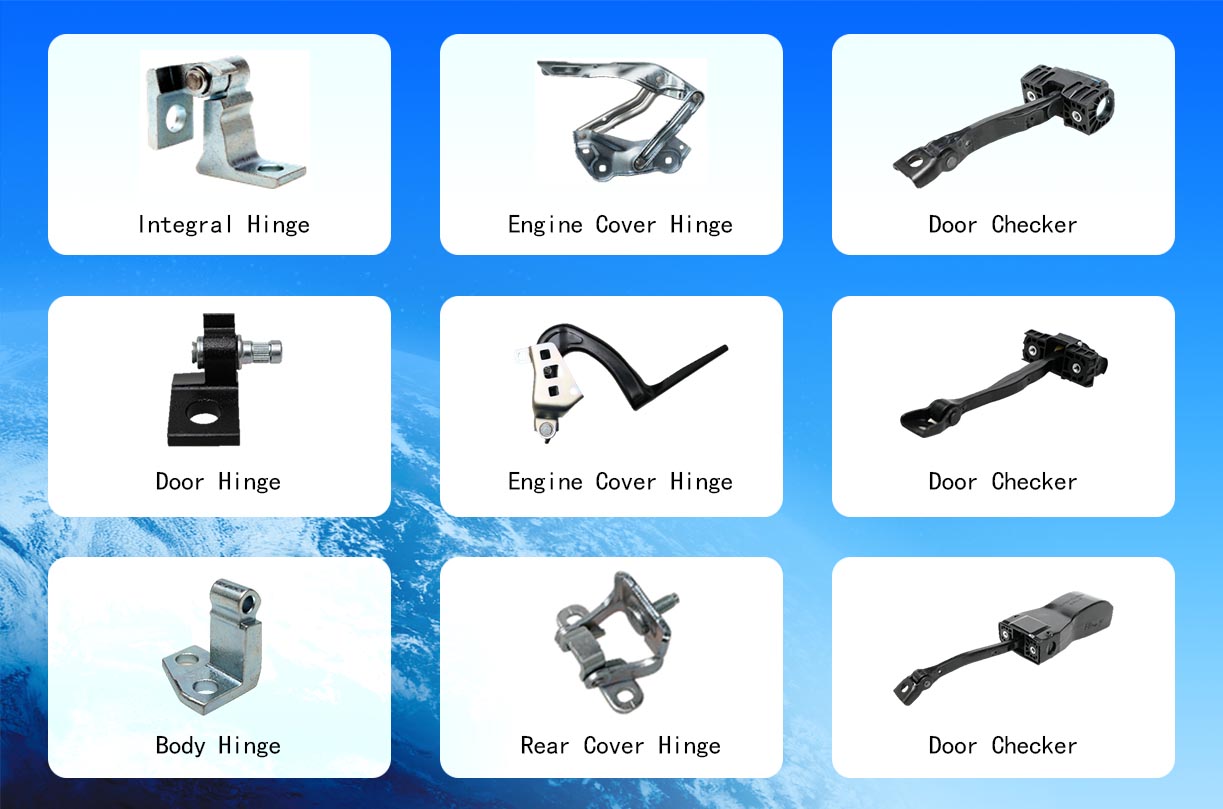

2025-04-17Shanghai Aolin Auto Safety System Co., Ltd. was established in 2011 and is located at No. 1, Yuanda Road, Jiading District, Shanghai. It is a high-tech enterprise integrating R&D, production, and sales. The company occupies an area of 7,500 square meters, equipped with modern standard workshops, advanced manufacturing facilities, and employs over 300 staff. It specializes in providing precision component manufacturing services for the global automotive industry, with products widely applied in electronic parking brake systems, steering systems, seating systems, and power transmission fields.  Core Business & Products: Focusing on precision machining, injection molding, and automated assembly as core technologies, the company boasts an annual production capacity of tens of millions of units. Its main products include intermediate shafts, worm gears, gears, rack gears, transmission sub-assemblies, four-door/two-hood hinges, stoppers, and other critical automotive components. With superior technical expertise, the company has become a long-term strategic partner to internationally renowned enterprises such as Continental, Yanfeng, KEIPER, and UAES.

Technology R&D & Quality Control: As a technology-driven enterprise, it has obtained over 40 intellectual property rights (including 20+ invention patents), with core technologies covering material optimization, precision machining processes, and automated production. Adhering strictly to the IATF 16949 international quality management standard, the company achieves "zero-defect" delivery through a digital control system, ensuring high reliability throughout the product lifecycle.

Production Equipment: German-made injection molding machines, Japanese automatic lathes, German thread rolling machines, Japanese CNC cylindrical grinders, heavy-duty milling machines, automated assembly lines, and online functional testing systems for final assemblies.

Testing & Inspection Equipment: Coordinate Measuring Machines (CMMs), 175 GMS Gear Measuring Centers, double-flank gear rolling testers, fatigue testing machines, spectrometers, torque testers, universal testing machines, flaw detectors, etc. These fully address requirements for dimensional accuracy, material performance, and durability testing.

Future Vision: The company will continue to deepen its focus on automotive safety systems, driven by innovation and anchored in quality, to deliver more efficient and reliable manufacturing services to global customers.

Core Business & Products: Focusing on precision machining, injection molding, and automated assembly as core technologies, the company boasts an annual production capacity of tens of millions of units. Its main products include intermediate shafts, worm gears, gears, rack gears, transmission sub-assemblies, four-door/two-hood hinges, stoppers, and other critical automotive components. With superior technical expertise, the company has become a long-term strategic partner to internationally renowned enterprises such as Continental, Yanfeng, KEIPER, and UAES.

Technology R&D & Quality Control: As a technology-driven enterprise, it has obtained over 40 intellectual property rights (including 20+ invention patents), with core technologies covering material optimization, precision machining processes, and automated production. Adhering strictly to the IATF 16949 international quality management standard, the company achieves "zero-defect" delivery through a digital control system, ensuring high reliability throughout the product lifecycle.

Production Equipment: German-made injection molding machines, Japanese automatic lathes, German thread rolling machines, Japanese CNC cylindrical grinders, heavy-duty milling machines, automated assembly lines, and online functional testing systems for final assemblies.

Testing & Inspection Equipment: Coordinate Measuring Machines (CMMs), 175 GMS Gear Measuring Centers, double-flank gear rolling testers, fatigue testing machines, spectrometers, torque testers, universal testing machines, flaw detectors, etc. These fully address requirements for dimensional accuracy, material performance, and durability testing.

Future Vision: The company will continue to deepen its focus on automotive safety systems, driven by innovation and anchored in quality, to deliver more efficient and reliable manufacturing services to global customers.

Jiading North Industrial Zone Industrial Base-Selected Product Display

Jiading Anting International Automobile City Industrial Base-Selected Product Display